ROPA Euro Tiger 5

Video Preview

Introduction

For the biggest agricultural fair in the world, the Bavarian family-run machine construction company ROPA presents for the first time the Tiger 5, with the new soil-protecting chassis with MICHELIN CerexBib tire technology, which was awarded with the Agritechnica innovations medal. The conceptually new chassis system with roll stabilization and slope compensation has already been implemented in 2-axle ROPA Panther. In the new Tiger 5 this concept was supplemented with a hydraulic chassis suspension of the rear axles, further developed on three drive axles and completed to perfection!

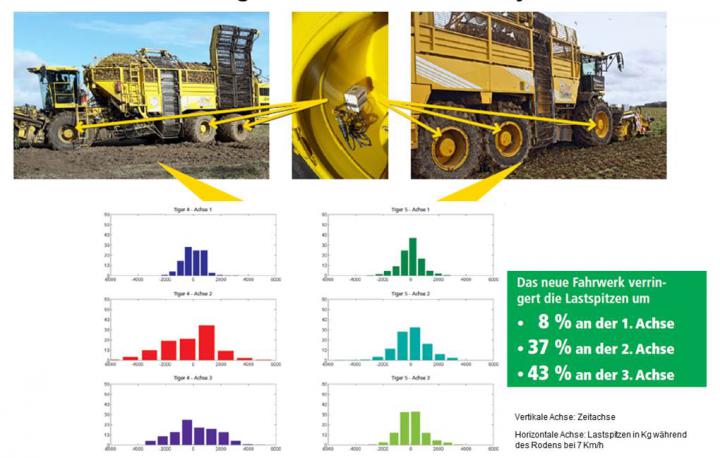

Hydraulic chassis system - roll stabilization with fully automatic wheel load and slope compensation

Specifically for the Tiger 5, ROPA has developed an innovative chassis concept with an oscillating front axle in conjunction with two hydraulically supported rear axles. Compared to previous chassis of 3-axle beet harvesters (the central axle is fixed to the frame) this reduces the sway of machine by one third! It is caused by hydraulic connection of stabilization cylinders at the front and rear axles of the one side, so that the ground unevenness at the wheel in level difference affects the frame only to 33 per cent - roll stabilization of the chassis. Thanks to the reduction of the chassis swing, the row and depth control is improved simultaneously, as the frame is averaged to the position of three axles. The hydraulic connection of the axles distributes the load always equally.

R-Soil Protect

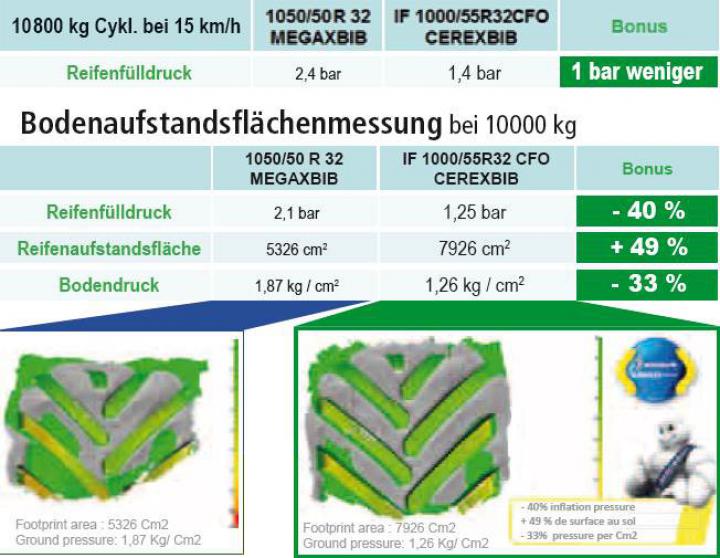

ROPA R-Soil protect is a floor gentle, hydraulic suspension system with new MICHELIN CerexBib tire technology which run for the first time with only 1.4 bar tire pressure for a sustainable root crop harvest. By combining all three hydraulically mounted axes, wheel loads are balanced with each other, and peak loads on a single wheel consistently excluded. The symbiosis of load balanced, hydraulic suspension and the new MICHELIN IF1000/55 R32 CerexBib tire generation leads to larger area contact with a clearly reduced contact surface pressure.

Slope compensation up to 10%

Unique among 3-axle beet harvesters is the automatic levelling system using six hydraulic cylinders and sensors. The entire vehicle is inclined to the slope by 10 % and thus held horizontally, the lifting unit runs itself scanning the soil surface. The slope stability is highly improved, even in extreme situations, the Tiger itself keeps stable where others harvesters would tip over. Furthermore, driving comfort increases as the driver remains in an upright seating position and doesn’t risk to slip out of the seat.

Significantly larger ground contact area for sustainable soil protection

The increased and soil-conserving tires of the new Tiger make him look mighty big and imposing. Good soil protection is maintained by the new 800/70 R38 Ultraflex tires at the front and 1050/50 R32 Michelin MegaXBib or. Michelin CerexBib IF1000/55R32 CFO at the rear axles even with full bunker of about 43 m³. The soil is protected and damping characteristics are improved at the same time.

New Mercedes engine with 15.6l volume capacity – very powerful and cost-saving

The power transfer in Tiger 5 of 626hp/460kW (Mercedes Benz 6-cylinder row engine with 15.6 l volume capacity, AdBlue and SCR-KAT euro-Mot 4 final) became even more efficient through reduced fuel consumption. A higher maximum torque of no less than 2,900 Nm is efficiently transmitted via new stepless traction drive.

Stepless CVR gearbox for efficient power transfer

This new stepless traction drive was specifically developed by ROPA, Omsi and Bosch-Rexroth for the Tiger 5 and its high driving power. The "Constant variable ROPA" gearbox (CVR) consists of three hydraulic motors on the compound gearbox and is located between the engine compartment and the third axle.

Up to 40 km/h at reduced rpm without switching gear

The speed of Tiger 5 is electronically restricted to 18 km/h in the lifting mode, during the road drive the Tiger moves continuously and "lively" from 0 to 40 km/h without switching and traction interruption! The maximum speed of 40 km/h can be reached by the Tiger at extremely economical 1,195 1/min. Lifting in the field can be performed at the lifting speed of only 1,175 1/min. Depending on the power requirement the rotational speed of the Tiger is regulated automotive up to 1,650 1/min. The multi-disk differential brakes integrated into the axles (protected from dirt) running in oil bath serve for the "taming" of the Tiger when required.

Direct power transmission with cardan shafts ensure a very high torque on all wheels

As a unique selling proposition on the market of 3-axle harvesters, the Tiger has a direct power transmission via directly linear situated cardan shafts from traction drive to the both rear axles and the front axle, which is a great advantage for better traction in changing or difficult soil and harvesting conditions. Thus, lead or lag between the axles are consistently excluded.

Automatic unfolding for completely automatic transformation from road drive into lifting action

A button touch is enough to „transform“ automatically ROPA Tiger 5 from the road drive mode to the field mode. Unloading conveyor, one meter wide ring elevator, bunker auger and other groups fold one by one and partially simultaneously. The sensor-controlled monitoring systems exclude operating errors and collisions. The entire folding process is performed by simultaneous activation of all functions to 50 % faster than before.

Super long unloading elevator for quick bunker unloading

The new extremely long unloading conveyor is located between the two rear axles and can be raised further due to higher tyres. A great advantage when overloading on driving alongside trailers, as it is performed shallower. It is 3-way foldable and 2000 mm wide for even simpler application of 10-meter-wide piles or easy overloading on trailer. The careful rubberized fingers guarantee high feeding capacity at short unloading time, only 50 sec with full bunker. The automatic bunker filling allows optimum traction under all harvest conditions by excellent weight distribution. Two ultrasound sensors measure the bunker filling, sum up the bunker charges, and save it in the impact database. The data export is possible via ISO-BUS.

Highlight!! – New cabin and operating concept of sugar beet harvester ROPA Tiger 5

The newly designed and considerably better mounted R-Cab cabin on hydraulic bushings ensures an optimized view of the improved PR2 lifting unit, whilst maintaining a physiologically adapted and comfortable seating position. A pleasant and gorgeous interior of the new cabin in combination with excellent sound insulation guarantee most comfortable operation. Extremely powerful fully LED working lights turn night into day.

ROPA combines under the name R-Concept its new intuitive operating philosophy. A large 12.1 inch touch screen with Wi-Fi interface performs as the information and command centre of the machine. From here the operator monitors the entire machine, receives information about operating conditions and performance data, adjusts functions and, thus, working results of the machine. The operation is performed dually, either with finger touch on the touch screen or with turning and pressing the rotate buttons „R-Select“ and „R-Direct“, which are situated in the ergonomically perfect position at the newly designed control panel in the handle of the multifunctional joystick (with integrated mini joystick). The thin control panel at the operator’s place suggests numerous possible adjustments for the ergonomic and comfortable seating position and at the same time increased visibility and heating of comfortable air seat as series. Premium class workplace.

The new intelligent three-point suspension with integrated measuring system allows even finer control of maintaining an optimum harvesting depth. As an advantage, this results in an even better lifting alongside with further reduced beet losses.

In summary, new developments of the Tiger 5 increase the daily output at reduced operating costs, simplifying maintenance and repair. The operator experiences an improved driving comfort during efficient and soil-protective harvesting of sugar beet.

The Tiger 5 is available from 2015 with the improved PR2h lifting unit with 6, 8 or 9 rows in different row widths. The defoliator unit can be selected between integral defoliator, defoliator with leaf ejection, all-round defoliator or rubber-defoliator with two rubber cleaning shafts.

Cabin

A newly designed and considerably better mounted R-Cab cabin ensures an optimized view of the lifting unit whilst maintaining a physiologically adapted and comfortable seating position. A pleasant and gorgeous interior of the new cabin in combination with excellent sound insulation guarantee most comfortable operation. Extremely powerful fully LED working lights turn night into day.

Operation with R-Concept Touch Screen

ROPA combines under the name R-Concept its new intuitive operating philosophy. A large 12.1 inch touch screen with Wi-Fi performs as the information and command centre of the machine. From here the operator monitors the entire machine, receives information about operating conditions and performance data, adjusts functions and, thus, working results of the machine. The operation is performed dually, either with finger touch on the touch screen or with turning and pressing the rotate buttons „R-Select“ and „R-Direct“, which are situated in the ergonomically perfect position at the newly designed control panel in the handle of the multifunctional joystick (with integrated mini joystick). The thin control panel at the operator’s place suggests numerous possible adjustments for the ergonomic and comfortable seating position and at the same time increased visibility and heating of comfortable air seat as series. Premium class workplace.

Chassis

Specifically for the Tiger 5, ROPA has developed an innovative chassis concept with an oscillating front axle in conjunction with two hydraulically supported rear axles. Compared to previous chassis of 3-axle beet harvesters (the central axle is fixed to the frame) this reduces the sway of machine by one third! It is caused by hydraulic connection of stabilization cylinders at the front and rear axles of the one side, so that the ground unevenness at the wheel in level difference affects the frame only to 33 per cent - roll stabilization of the chassis. Thanks to the reduction of the chassis swing, the row and depth control is improved simultaneously, as the frame is averaged to the position of three axles. The hydraulic connection of the axles distributes the load always equally.

Very large swing angle of the axles

No twisting of the main frame, also at oblique crossing of edges or ridge.

Drive

The speed of Tiger 5 is electronically restricted to 18 km/h in the lifting mode, during the road drive the Tiger moves continuously and "lively" from 0 to 40 km/h without switching and traction interruption! The maximum speed of 40 km/h can be reached by the Tiger 5 at extremely economical 1,195 1/min. Lifting in the field can be performed at the lifting speed of only 1,175 1/min. Depending on the power requirement the rotational speed of the Tiger is automotive regulated up to 1,650 1/min. The multi-disk differential brakes integrated into the axles (protected from dirt) running in oil bath serve for the "taming" of the Tiger when required.

The power transfer in Tiger 5 of 626hp/460kW became even more efficient through reduced fuel consumption. A higher maximum torque of no less than 2,900 Nm is transferred with optimized efficiency.

Stepless CVR gearbox for efficient power transfer

This new stepless traction drive was specifically developed by ROPA, Omsi and Bosch-Rexroth for the Tiger 5 and its high driving power. The "Constant variable ROPA" gearbox (CVR) consists of three hydraulic motors on the compound gearbox and is located between the engine compartment and the third axle.

Direct power transmission with cardan shafts ensures a very high torque on all wheels

As a unique selling proposition on the market of 3-axle harvesters, the Tiger has a direct power transmission via directly linear situated cardan shafts from traction drive to the both rear axles and the front axle, which is a great advantage for better traction in changing or difficult soil and harvesting conditions. Thus, lead or lag between the axles are consistently excluded.

Slope Compensation

Slope compensation up to 10%

Unique among 3-axle beet harvesters is the automatic levelling system using six hydraulic cylinders and sensors. The entire vehicle is inclined to the slope by 10 % and thus held horizontally, the lifting unit runs itself scanning the soil surface. The slope stability is highly improved, even in extreme situations, the Tiger itself keeps stable where others harvesters would tip over.

Tires

Significantly larger ground contact area for sustainable soil protection

The increased and soil-conserving tires of the new Tiger make him look mighty big and imposing. Good soil protection is maintained by the new 800/70 R38 Ultraflex tires at the front and 1050/50 R32 Michelin MegaXBib or Michelin CerexBib IF1000/55 R 32 tyres at the rear axles even with full bunker of about 43m³ / 30t. The soil is protected and damping characteristics are improved at the same time.

Defoliator

Efficient topping, robust, low wear - structurally similar to ROPA euro-Tiger V8-4

The depth control is achieved via 2 sensor wheels mounted directly at the front of the defoliator housing. The setting can be altered individually right and left or synchronized with the joystick. The operator monitors the set depth by means of two display scales. The adjustable hydraulic loading of the flail unit is shown on the colour terminal.

Four different types of defoliator unit can be supplied depending on requirements:

ROPA integral defoliator, a standard recommendation for normal harvesting conditions

Leaves are mulched with robust defoliator’s knives from the beet crowns and spread between the rows. Therefore, beet leaves with all their nutrients are evenly delivered to the soil -> an optimal condition for further soil cultivation as green waste transforms fast into humus. The rotor rmp can be conveniently adjusted, from the cabin from rough to fine structured mass.

Similarly, the all-round defoliator (pictured above, right) can be switched to integral approach, so that the beet field can be lifted up without “opening up the field“, working off one end.

PAS - leaf ejection

PAS - Integral leaf-layer

PAS - ROPA all-round defoliator with 380 mm leaf auger and large large leaf-spreader

=> can be changed from the cabin for either integral topping or leaf ejection

With the ROPA all-round defoliator you are ready for all requirements. Optionally, the shredded beet leaves are placed between the rows or spread by leaf auger/leaf-spreader over the lifted area. You can easily switch by pressing a button in the cabin. To harvest the beet leaves (for biogas or dairy) an optional leaf conveyor can be attached.

Comfortable defoliator maintenance position

The defoliator can be raised hydraulically up to 90° above the lifting unit to provide access for maintenance.

This can be operated with a button tip from the cab as well as at ground level at the unit - without inserting any bolts.

Rubber defoliator

Defoliator to harvest the whole beet crowns

ROPA has further developed the sugar beet leaves cleaning. At the newly developed defoliator with rubber flails from ROPA the both fully hydraulic driven cleaning rotors can be adjusted at the rotation speed independently from the other – unique!

Each rotor shaft can be adjusted at the height independently from the other. As a result, the operator can react quickly and effectively to different requirements due to changing beet crops. Various settings can be stored and accessed on the joystick using a memory function.

Micro Topper

ROPA Micro-Topper - maximum yields without additional efforts

ROPA Micro-Topper is the best practical solution that simultaneously meets the requirements of farmers, contractors and sugar mills! ROPA Micro-Topper provides the ability to harvest the whole beet bodies without tops. At reduced rounds per minute the topper is lifted so high that each beet crown is remained with the leaf cutting. Thus, the useful life of defoliator cutter is increased (less contact with the ground /stones), while reducing the fuel consumption. The comb of the Micro-Topper follows each beet crown, adjusting the trimming gap to the size of the crown, so that the beet is cut not too much and returns maximum yield. The intensity of the cut can be easily adjusted from the cabin. You may choose between topping and "shaving" of leaves only (micro-topping).

The topping shaft that is used is so high, that the leaf cuttings are remained on the beet. The comb of Micro-Topper then detects the height of each beet head and “shaves off” the leaves.

Lifting Unit

Non-jamming, effective and gentle.

The PRh lifting unit is equipped with counter-rotating oscillating shares and maintenance-free stone protection. Lifting units are supplied with 45 cm and 50 cm. The variable lifting unit can be easily switched from 45cm to 50 cm from the cabin. The 900 mm large depth wheels combined with the intelligent three-point suspension guarantee accurate depth control of the lifter. Minimum maintenance costs are required thanks to adjustable taper roller bearing in drives and oscillating share drive. The comb of the Micro-Topper follows each beet crown, adjusting the trimming gap to the size of the crown, so that the beet is cut not too much and returns maximum yield. The intensity of the cut can be easily adjusted from the cabin. You may choose between topping and "shaving" of leaves only (micro-topping).

The rollers height of the PR lifting unit can be adjusted independently from the height of the share beams. 900 mm gauge wheels ensure a proper ground following and press weeds and leaf material before the lifting shares to the ground.

Operation of the hydraulic stone protection

The impact pressure of the stone protection is electronically set by the operator from his seat. Stone protection is achieved by a hydraulic cylinder pressing from above onto the share body.

With stones or obstacles the crowd body can make way upwards. This system totally eliminates incidental movement at the front of the share body where most incidents occur.

Depth control wheels with constant row distance

Depth control wheels with variable row width of 45/50 cm, adjustable with a button push from the cabin

The speed of the oscillating shares drive is adjustable during operation. The oscillating shares are driven by a spur gear mechanism. The bearing box is equipped with high quality, adjustable roller bearings. By adjusting the roller bearings (every 1-2 seasons) their operating time – compared to traditional systems – is extended many times over.

Excellent view across the topper/Micro-Topper

Excellent view across the lifting unit -> the operator watches the beet row and the operation of the Micro-Topper.

Each share unit eqipped with a maintenance-free linear guide adjusts up to 70 mm sidways to the beet row. Long hinged connecting rods minimize transverse force and improve row alignment.

Hydraulic adjustment upwards of the share beam - independently from the rollers height

The harvesting depth of the shares and their positioning left and right can be adjusted manually or synchronized with the joystick.

Hydraulic height adjustment of the harvester roller gear

The lifting rollers movement height can be hydraulically adjusted independent of lifting depth at all PRh lifting units. So that even at the deep lifting less soil, stones and leaves get into the machine.

ROPA lifting share angle and distance are optimally adjustable to six positions for more careful beet treatment.

To ensure that the right front wheel maintains a wider distance from the next row the first four lifting rollers and the lifting unit can be moved 20 cm right or left, depending on direction, following initial lifting with the 6-row harvester (this applies only to row widths of 45 cm a/o 50 cm).The 5th and 6th lifting rollers can not be adjusted. By this arrangement optimal quick conveyance of the beet onto the infeed conveyer is ensured. Two short, overlapping lifting rollers, right and left at the rear of the unit, ensure that under heavy soil conditions optimal conveying and cleaning is achieved. The speed of the four front rollers is continuously adjustable to optimize cleaning.

Beet Tank

43 m³ beet tank

The automatic bunker filling allows optimum traction under all harvest conditions by excellent weight distribution. Two ultrasound sensors measure the bunker filling, sum up the bunker charges and save it in the database. The data export is possible via ISO-BUS.

Unloading Conveyor

Super long unloading conveyor for quick beet tank unloading

The new extremely long unloading conveyor is located above the two rear axles and can be raised further due to higher tires. A great advantage when overloading on driving alongside trailers, as it is performed shallower.

The careful rubberized fingers guarantee high feeding capacity at short unloading time, only 50 sec with full bunker.

It is 3-way foldable and 2000 mm wide for even simpler application of 10-meter-wide piles or easy overloading on trailer.

Cleaning

Careful, thorough and flexible.

Turbine gates are individually adjustable in height, inclination and rotation and segmental interchangeable.

The hydraulically tensioned conveyor transfers the beet quickly to the first cleaning turbine. Due to the front axle the best throughput of beet is ensured without stopping the flow or damaging them. The operator can continuously adjust the speed of the transfer conveyer and, if necessary, reverse it. Three turbines clean the beet thoroughly and then convey it on swiftly.

The guide gates consisting of gates or sprung tin gates (or a combination of both) can be hydraulically adjusted upwards from the seat. This increases the cleaning intensity. Also in wet harvest conditions Panther guarantees the necessary distance to the ground. The biggest ground clearance in the deepest point of the cleaning system makes it easily accessible for maintenance.

Ten cleaning programmes can be set in advance (from extremely light to very intensive). Any turbine adjustment is made via a +/- button. Control of the turbines is coupled with an automatic rev adjustment. This eliminates interruptions in the cleaning process.

The sugar beet is conveyed gently into the beet tank via a 900 mm wide elevator at an hydraulically adjustable speed. For driving on the road the ring elevator, unloading conveyer, beet tank auger, with adjustable back and front heights and two beet tank stabilizers are folded hydraulically into the tank.

Technical Data

Ropa Tiger 5

Engine:

Mercedes Benz diesel engine OM473LA 6 cylinders in row, exhaust gas norm EUROMOT 4, 460 kW (626 hp), 15.6 l capacity, max. torque of 2,900 Nm, operating speed 1,125 1/min automotive up to max 1,650 1/min, fuel consumption display l/ha and l/h at the terminal.

Traction drive:

Completely new traction drive construction with stepless CVR gearbox for efficient power traction, consisting of three hydraulic motors on the compound gearbox, from 0 up to 40 km/h continiously without any interruption (no gear change or switching). 40 km/h in road mode at 1,195 1/min, 17.5 km/h in the field at 1,220 1/min.

Tires:

1st axle - 800/70 R38 Michelin CerexBib

2nd axle - 1050/50 R32 Michelin MegaXBib

3rd axle - 1050/50 R32 Michelin MegaXBibFirst

Only 1,4 bar front / 1,9 bar rear at full bunker load. Large surface area offers high operational safety even under wet conditions or on slopes.

Hydraulic chassis:

An innovative chassis concept with an oscillating front axle in conjunction with two hydraulically supported rear axles.

With the help of 6 hydraulic cylinders, the chassis can be inclined on both sides by approx. 10 % to the slope, the slope compensation is automatically controlled by two electronic inclination sensors.

Roll stabilization due to hydraulic levelling of the oil volume in the cylinders of the one vehicle side.

Cooling system:

Side-by-side arrangement of cooling elements for loading air and water, dirt resistant positioning of the coolers at rear top side. Hydrostatically stepless propelled and automatically reversible fan.

Hydraulics:

Pump distributor gears with pressurized air lubrication and gear oil cooling system, Bosch-Rexroth, operational load sensing hydraulics from Bosch-Rexroth, Bucher and Hydac with excellent capacity.

Cabin:

New cabin positioning with hydraulic bushings, sound-proof and tinted all-round glazing with low-line vision, heating and ventilating system (automatic air-conditioning), R-Concept control panel, 12,1“ R-Touch display, joystick-operation, autopilot, cruise control, machine diagnostics incl. diesel engine fully integrated in the display, air-sprung Grammer comfort seat with heating, Bluetooth MP3 audio system with radio, base console for telephone, whole screen wipers, 2 LED-internal lights, video-monitor with standard reversing camera.

Bunker capacity:

about 43 m³

Defoliator unit:

PIS - integral defoliator unit with leaf spreading between beet rows, 2 depth-control wheels.

PAS - all-round defoliator unit, push-button operation from the driver’s seat, can be changed for either integral topping or leaf ejection to the left, 2 depth-control wheels (4 depth-control wheels optionally).

PBS - defoliator unit with leaf ejection to the left, leaf-spreader and 2 depth-control wheels (4 depth-control wheels optionally).

PES - rubber defoliator with leaf spreading between beet rows, 2 depth-control wheels.

Lifting unit:

PR2 – 6-row lifting unit, 45 cm, 50 cm or variable, with faster shaking shares drive via axial piston motor, hydraulic stone protection, 900 mm depth-control wheels and adjustable taper roller bearing in shaking shares drive and lifting unit gears, defoliator positioning enables raising for maintenance by 90 degrees for optimum control and service of flails, scalping knife and lifting shares, distance between fourth and fifth lifting rollers variably adjustable, excellent overview of lifting unit and scalper without additional cameras.

Cleaning:

800 mm wide infeed conveyor, 1,700 mm first strainer wheel diameter, 1,500 mm second and third strainer wheels diameter, 1000 mm wide elevator, guide grids height of all strainer wheels is independently adjustable, partial replacement of guide grids by spring tines is possible.

Electrics / electronics:

Integrated net of 24 volt, generator of 150 amps, 24 LED operating lights from Hella, 2 x 12 volt sockets for radio or telephone etc., CAN-BUS computer system with integrated diagnosis of all components connected to the terminal, software update per USB interface possible.

Unloading conveyor:

Triple-foldable conveyor for even easier establishment of 10-meter-wide clamps. Beet protective PU cam for high throughput and short unloading, unloading conveyor width is 200 cm for even easier trailer loading, fast bunker emptying in less than a minute, as longitudinal conveyors are made bias to cross conveyors.

Overloading height: up to 4.00 m

Yield indicator:

2 ultra-sound sensors measure the bunker content, full bunkers (and partly loaded bunkers) are added up and automatically recorded in the database.

Dimensions:

Length: 14.99 m

Height: 4.00 m (transport mode)

Width: 3.00 m (6-rows at 45 cm width),

3.30 m (6-rows at 50 cm width and 45-50 cm variable)

Fuel tank: 1050 l diesel, 130 l Ad Blue

Standard:

Central lubrication system, fuel consumption measurement, air-conditioning, manual slope compensation, 40 km/h.

Optional:

Leaf-spreader with stone protection, skids at scalper, forged widia shares, lifting rollers with hard welded finish, guide grids segments with spring tines in 1-3 strainer wheels, agitator in the strainer wheel 2, strainer wheel camera, unloading conveyor camera, 2 LCD color displays, 2 LED high beam headlamps, data printer, via Wi-Fi Connect: R-Transfer Basic with data export to Ropa app, R-Transfer Professional with data import and export to Ropa-App or USB stick. Distance Control Assistant, GPS driving speed sensor, leaf collecting equipment (only for defoliator with leaf auger), bio-hydraulic oil, automatic slope compensation, additional chassis (obligatory in Germany).